Evolution of microstructure of nanocrystalline SiC and diamond powders

in high-pressure high-temperature conditions

R.Pielaszek1,2), M.Avdeev3), E.Grzanka1,2),

B.Palosz1), S.Gierlotka1), S.Stel'makh1)

1) High Pressure Research Centre, Polish Academy of Sciences,

Sokolowska 29, 01-142 Warsaw, Poland

2) Warsaw University, Department of Physics, Hoza 69, 00-681

Warsaw, Poland

3) Budapest Neutron Centre, Budapest, Hungary

There is an increasing interest in the nanocrystalline materials

with respect to their fundamental properties as well as potential applications

for fabrication of high-tech construction and electronic ceramics [1].

Knowledge of microstructure, understood as morphology of crystallites,

their size, shape and spatial arrangements during sintering is essential

for technology of such materials. For us it's also basis (that has to be

defined) for further strain analysis in high-pressure investigations [2,3].

Three samples of nanometric diamond, six of SiC and two

samples of their ceramics obtained during high-pressure, high-temperature

sintering experiments were examined. One sample of SiC of size of few microns

in diameter was examined as a reference.

Analysis of the Small Angle Neutron Scattering (SANS)

data gave microstructure characteristics of the materials. In

all cases we were able to derive surface fractal dimension Ds.

In four cases shape of lowest-angle part of the scattering curve was clear

sufficiently to derive mass fractal dimension Dm.

See Tab.1 below:

|

Sample ID

|

Material

|

Size of grain

|

Comment

|

Dm(mass fractal dimension)

|

Ds(surface fractal dimension)

|

| 157k |

SiC |

3.9nm |

powder |

2.08(3) |

2.33(8) |

| h1k |

SiC |

few nm |

powder |

|

2.7(1) |

| w3k |

SiC |

few nm |

powder |

|

2.2(1) |

| keil1 |

SiC |

few nm |

powder |

|

2.32(4) |

| keil2 |

SiC |

more than few nm |

powder |

|

2.12(5) |

| 483 |

SiC |

|

powder |

|

2.0 |

| 483p |

SiC |

|

sintered 483 |

|

2.02(2) |

| a16 |

diamond |

|

powder |

1.86(3) |

2.12(4) |

| a16p |

diamond |

|

sintered a16 |

1.40(4) |

2.34(5) |

| atm |

diamond |

|

powder |

1.86(3) |

2.34(3) |

| dalan |

diamond |

|

powder |

|

2.27(1) |

| ref |

SiC |

microns |

reference SiC powder |

|

2.24(3) |

Tab.1.Mass and surface fractal

dimensions of nanocrystalline SiC and diamond powders and (483p, a16p)

sintered powders.

We found that:

-

all nanocrystalline powders examined show fractal structure

of pores and/or surface of the grains

-

surface roughness of most of the powders is similar (Ds

is in range 2.1-2.3) for both: SiC and diamond

-

pores structure of SiC 157k sample seems to be build of 2D

planes isolating relatively big and dense SiC agglomerates

-

pores structure of diamond a16 and atm samples show less

porosity wire-shaped rather than 2D

-

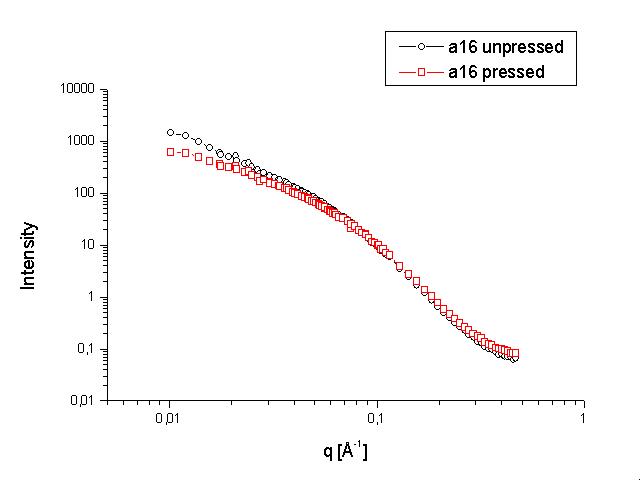

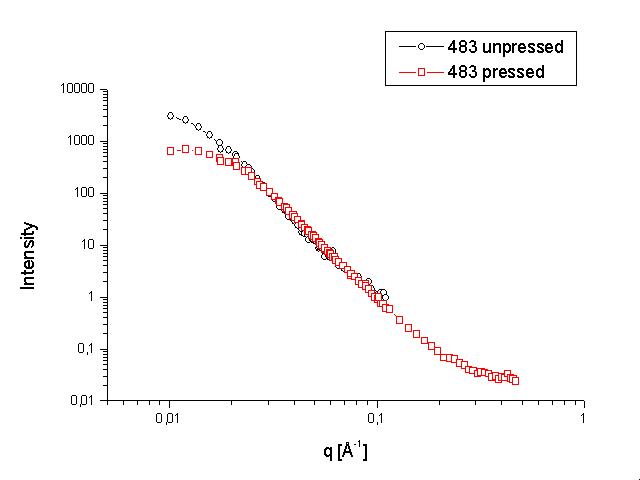

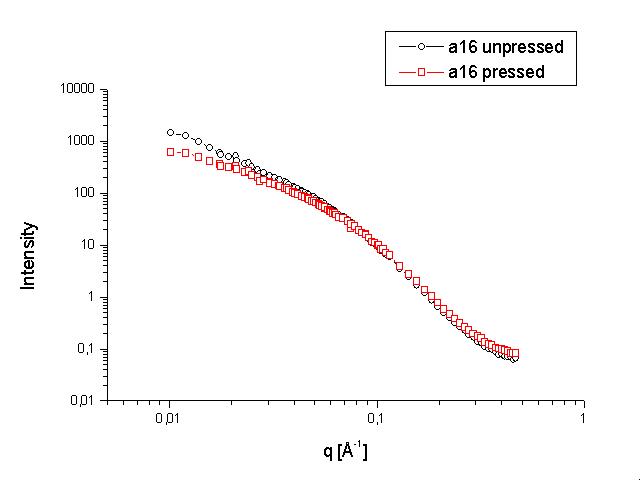

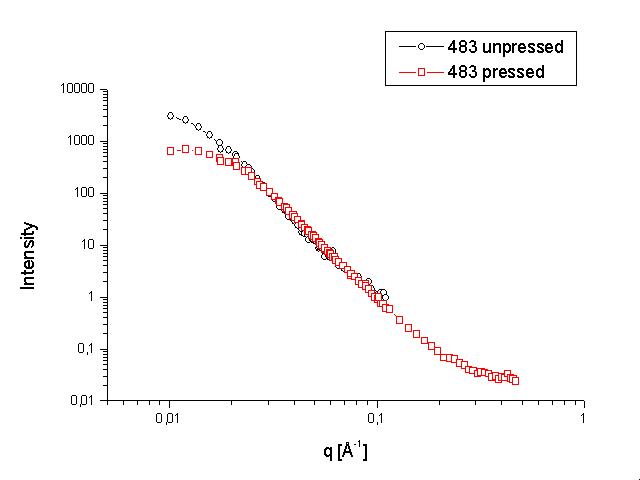

high-pressure high-temperature sintering decreases mass porosity

(Dm: 1.86->1.40) and increases roughness of the surface (Ds:

2.12->2.34) - see Fig.1 below:

|

|

Fig.1. High-pressure high-temperature

sintering decreases slope of lowest-angle part of the scattering curve

(thus pores mass fractal dimension Dm) for both SiC and diamond

nanocrystalline powders

References:

[1] B.Palosz, et al., HASYLAB Annual Report, Vol.I p.587

(1998)

[2] R.Pielaszek, et al., Material Research Society Symp.

Proceedings, Vol.501 p.305-310 (1998)

[3] R.Pielaszek, et al., Materials Science Forum, Vol.321-324

p.346-351 (1999)